Rotate your tablet

for a better experience

Rotate your tablet

for a better experience

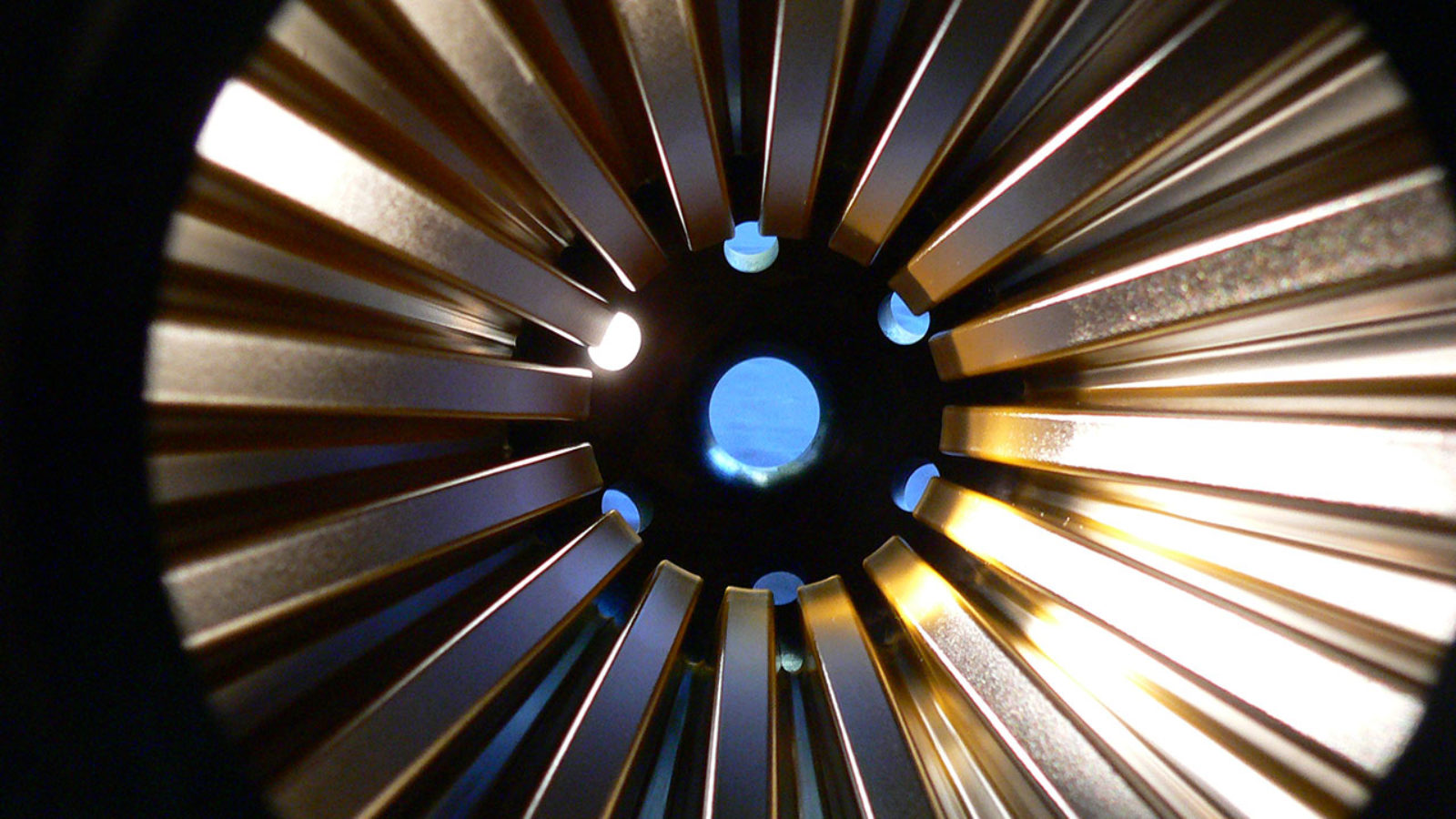

APP is perfectly equipped for the production of solid composite propellant grains. In our climate controlled production facility APP has the following equipment available:

Assembly, Inspection and Testing

Our assembly, inspection and test facilities have several rooms for assembly of igniters and gas generators. For assembly activities requiring a high cleanliness level, a class 100.000 / ISO 8 clean room is available.

A range of dedicated equipment is available for the assembly of our products:

Facilities for inspections and testing:

Very important for product development and product assurance during production is our firing test facility. In this facility APP can test propellant samples but also complete products. Tests can be performed at ambient, low or high temperature levels and can measure internal gas pressure, temperature, mass flow and thrust.